Supesplastic forming

Superplastic forming is an industrial process used for creating precise and complex components out of superplastic materials.

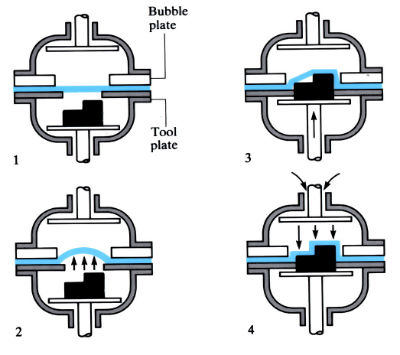

The material is first heated up to promote superplasticity. For titanium alloys e.g. Ti 6Al 4V and some stainless steels this is around 900 °C (1,650 °F) and for aluminum alloys e.g. AA5083 it is between 450 and 520 °C. In this state the material becomes soft so processes usually used on plastics can be applied, such as thermoforming, blow forming, and vacuum forming. Inert gas pressure is applied on the superplastic sheet forcing it into a female die.

Advantage of superplastic forming:

* Lower strength requires the tooling

* The mere complex forms can be formed

* No residual stress is induced during the parts forming

* Tooling cost low

* High rate of forming

Materials:

The superplastic forming process is suitable for particular materials only. It that having excellent grain structure of less than 10 to 15 um in size.

The below material of SFP:

* Iron-based high-carbon alloy

- Incol 100

- 7475- T6 aluminium alloy

- Incoloy 718

- T1- 6A1- 4v titanium alloy

The machine's sizes are also much smaller. A superplastic former machine smaller than a stamping machine.