hvac systems cool

A heating, ventilation, and air conditioning (HVAC) system is designed to achieve the environmental requirements of the comfort of occupants and a process.

HVAC systems are more used in different types of buildings such as industrial, commercial, residential, and institutional buildings. The primary mission of the HVAC system is to satisfy the thermal comfort of occupants by adjusting and changing the outdoor air conditions to the desired conditions of occupied buildings. Depending on outdoor conditions, the outdoor air is drawn into the buildings and heated or cooled before it is distributed into the occupied spaces, then it is exhausted to the ambient air or reused in the system. The selection of HVAC systems in a given building will depend on the climate, the age of the building, the individual preferences of the owner of the building and a designer of a project, the project budget, and the architectural design of the buildings.

So basically HVAC systems are your friends except if you like being uncomfortably cold or hot.

HVAC systems can be classified according to necessary processes and distribution processes. The required processes include the heating process, the cooling process, and the ventilation process. Other processes can be added such as the humidification and dehumidification processes. This process can be achieved by using suitable HVAC equipment such as heating systems, air-conditioning systems, ventilation fans, and dehumidifiers. The HVAC systems need the distribution system to deliver the required amount of air with the desired environmental condition. The distribution system mainly varies according to the refrigerant type and the delivery method such as air handling equipment, fan coils, air ducts, and water pipes.

HVAC system selection

System selection depends on three main factors including the building configuration, the climate conditions, and the owner's desire. The design engineer is responsible for considering various systems and recommending more than one system to meet the goal and satisfy the owner of a building. Some criteria can be considered such as climate change (e.g., temperature, humidity, and space pressure), building capacity, spatial requirements, costs such as capital cost, operating cost, maintenance cost, life cycle analysis, and reliability and flexibility.

However, the selection of a system has some constraints that must be determined. These constraints include the available capacity according to standards, building configuration, available space, construction budget, the available utility source, and heating and cooling building loads.

. Basic components of an HVAC system

The basic components or equipment of an HVAC system that delivers conditioned air to satisfy the thermal comfort of space and occupants and the achieve the indoor air quality are listed below [3]:

Mixed-air plenum and outdoor air control

Air filter

Supply fan

Exhaust or relief fans and an air outlet

Outdoor air intake

Ducts

Terminal devices

Return air system

Heating and cooling coils

Self-contained heating or cooling unit

Cooling tower

Boiler

Control

Water chiller

Humidification and dehumidification equipment

Classification of HVAC systems

The major classification of HVAC systems is the central system and decentralized or local system. Types of a system depend on addressing the primary equipment location to be centralized as conditioning for the entire building as a whole unit or decentralized as separately conditioning a specific zone as part of a building. Therefore, the air and water distribution system should be designed based on system classification and the location of primary equipment. The criteria mentioned above should also be applied in selecting between two systems. Table 1 shows the comparison of central and local systems according to the selection criteria.

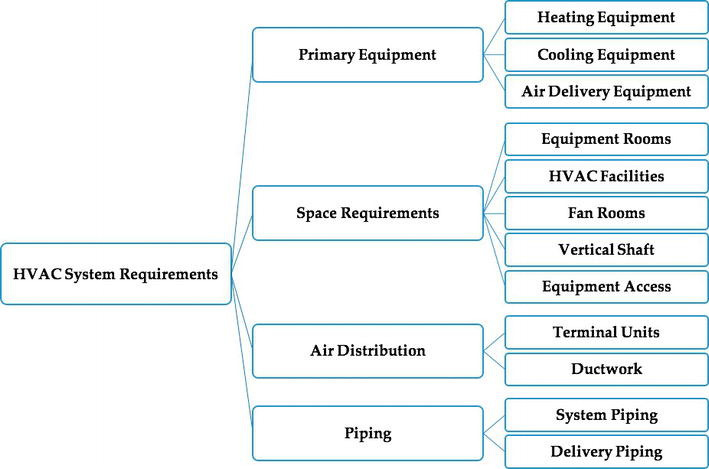

HVAC system requirements

Four requirements are the bases for any HVAC system. They need primary equipment, space requirement, air distribution, and piping, as shown.

Primary equipment includes heating equipment such as steam boilers and hot water boilers to heating buildings or spaces, air delivery equipment as packaged equipment to deliver conditioned ventilation air by using centrifugal fans, axial fans, and plug or plenum fans, and refrigeration equipment that delivers cooled or conditioned air into space. It includes cooling coils based on water from water chillers or refrigerants from a refrigeration process.

Space requirement is essential in shaping an HVAC system to be central or local. It requires five facilities like the following:

Equipment rooms: since the total mechanical and electrical space requirements range between 4 and 9% of the gross building area. It is preferable to be centrally located in the building to reduce the long duct, pipe, and conduit runs and sizes, to simplify shaft layouts, and centralize maintenance and operation.

HVAC facilities: heating equipment and refrigeration equipment require many facilities to perform their primary tasks of heating and cooling the building. The heating equipment requires boiler units, pumps, heat exchangers, pressure-reducing equipment, control air compressors, and miscellaneous equipment, while the refrigeration equipment requires water chillers or cooling water towers for large buildings, condenser water pumps, heat exchangers, air-conditioning equipment, control air compressors, and miscellaneous equipment. The design of equipment rooms to host both pieces of equipment should consider the size and the weight of equipment, the installation and maintenance of equipment, and the applicable regulations to combustion air and ventilation air criteria.

Fan rooms contain the HVAC fan equipment and other miscellaneous equipment. The rooms should consider the size of the installation and removal of fan shafts and coils, the replacement, and maintenance. The size of fans depends on the required airflow rate to condition the building, and it can be centralized or localized based on availability, location, and cost. It is preferable to have easy access to outdoor air.

Vertical shaft: provide space for air distribution and water and steam pipe distribution. The air distribution contains HVAC supply air, exhaust air, and return air ductwork. Pipe distribution includes hot water, chilled water, condenser water, and steam supply, and condenser return. The vertical shaft includes other mechanical and electrical distribution to serve the entire building including plumbing pipes, fire protection pipes, and electric conduits/closets.

Equipment access: the equipment room must allow the movement of large, heavy equipment during the installation, replacement, and maintenance.

Air distribution considers ductwork that delivers the conditioned air to the desired area in a direct, quiet, and economical way as possible. Air distribution includes air terminal units such as grilles and diffusers to deliver supply air into space at low velocity; fan-powered terminal units, which use an integral fan to ensure the supply of air to the space; variable air volume terminal units, which deliver a variable amount of air into the space; all-air induction terminal units, which controls the primary air, induces return air, and distributes the mixed air into space; and air-water induction terminal units, which contains a coil in the induction air stream. All the ductwork and piping should be insulated to prevent heat loss and save building energy. It is also recommended that buildings should have enough ceiling spaces to host ductwork in the suspended ceiling and floor slab, and can be used as a return air plenum to reduce the return ductwork.

The piping system is used to deliver refrigerant, hot water, cooled water, steam, gas, and condensate to and from HVAC equipment in a direct, quiet, and affordable way. Piping systems can be divided into two parts: the piping in the central plant equipment room and the delivery piping. HVAC piping may or may not be insulated based on existing code criteria.

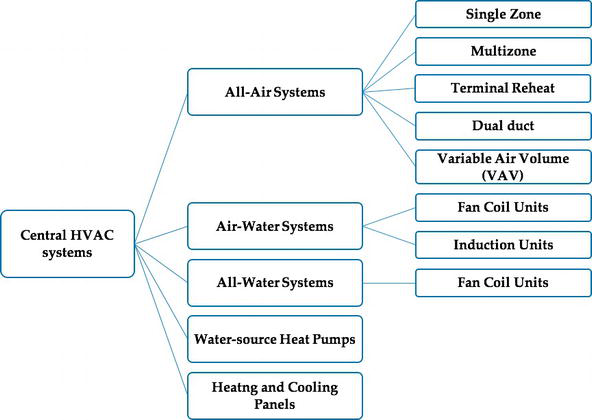

Central HVAC systems

A central HVAC system may serve one or more thermal zones, and its major equipment is located outside of the served zone(s) in a suitable central location whether inside, on top, or adjacent to the building [4, 5]. Central systems must condition zones with their equivalent thermal load. Central HVAC systems will have as several control points such as thermostats for each zone. The medium used in the control system to provide the thermal energy sub-classifies the central HVAC system, as shown.

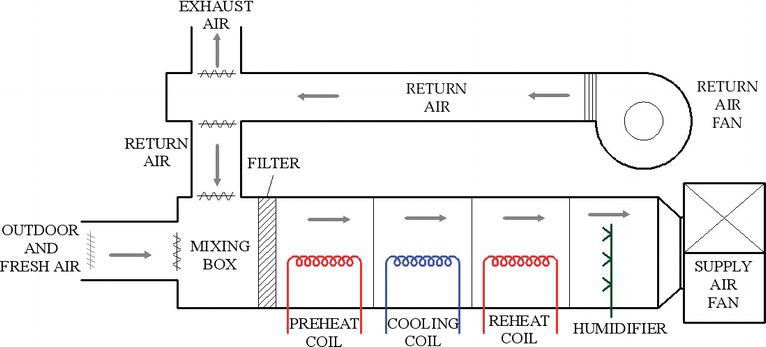

The thermal energy transfer medium can be air or water or both, which represent as all-air systems, air-water systems, all-water systems. Also, central systems include water-source heat pumps and heating and cooling panels. All of these subsystems are discussed below. Central HVAC system has combined devices in an air handling unit, as shown in Figure 3, which contains supply and return air fans, humidifier, reheat coil, cooling coil, preheat coil, mixing box, filter, and outdoor air.

All-air systems

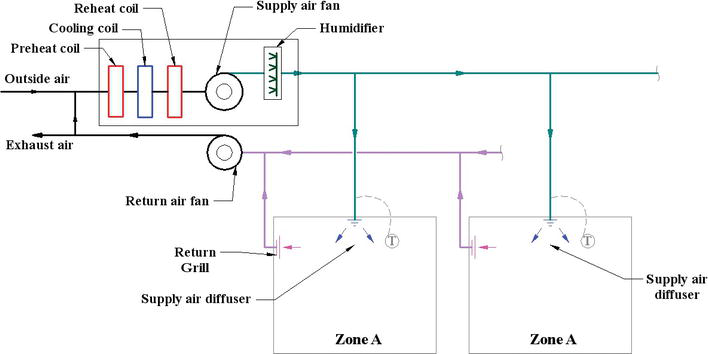

The thermal energy transfer medium through the building delivery systems is air. All-air systems can be sub-classified based on the zone as single zone and multizone, airflow rate for each zone as constant air volume and variable air volume, terminal reheat, and dual duct .

Single zone

A single-zone system consists of an air handling unit, a heat source and cooling source, distribution ductwork, and appropriate delivery devices. The air handling units can be wholly integrated where heat and cooling sources are available or separate where heat and cooling sources are detached. The integrated package is most commonly a rooftop unit and connected to ductwork to deliver the conditioned air into several spaces with the same thermal zone. The main advantage of single-zone systems is simplicity in design and maintenance and low first cost compared to other systems. However, its main disadvantage is serving a single thermal zone when improperly applied.

In a single-zone all-air HVAC system, one control device such as a thermostat located in the zone controls the operation of the system, as shown in Figure 4. Control may be either modulating or on–off to meet the required thermal load of the single zone. This can be achieved by adjusting the output of the heating and cooling source within the packaged unit.

Although few buildings can be a single thermal zone, a single zone can be found in several applications. One-family residential buildings can be treated as single-zone systems, while other types of residential buildings can include different thermal energy based on the occupation and building structure. Movements of occupants affect the thermal load of the building, which results in dividing the building into several single zones to provide the required environmental condition. This can be observed in larger residences, where two (or more) single zone systems may be used to provide thermal zoning. In low-rise apartments, each apartment unit may be conditioned by a separate single-zone system. Many sizeable single-story buildings such as supermarkets, and discount stores, can be effectively conditioned by a series of single-zone systems. Large office buildings are sometimes conditioned by a series of separate single-zone systems.

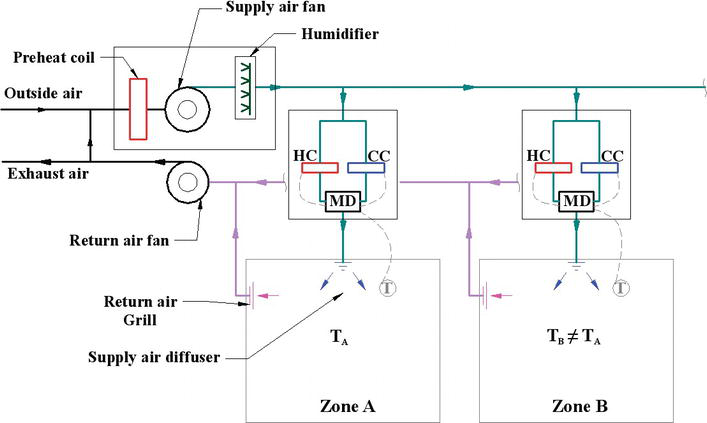

Multi-zone

In a multi-zone all-air system, individual supply air ducts are provided for each zone in a building. Cold air and hot (or return) air are mixed at the air handling unit to achieve the thermal requirement of each zone. A particular zone has its conditioned air that cannot be mixed with that of other zones, and all multiple zones with different thermal requirements demand separate supply ducts, as shown in Figure 5. Multi-zone all-air system consists of an air handling unit with parallel flow paths through cooling coils and heating coils and internal mixing dampers. It is recommended that one multi-zone serve a maximum of 12 zones because of physical restrictions on duct connections and damper size. If more zones are required, additional air handlers may be used. The advantage of the multi-zone system is to adequately condition several zones without energy waste associated with a terminal reheat system. However, leakage between the decks of the air handler may reduce energy efficiency. The main disadvantage is the need for multiple supply air ducts to serve multiple zones.

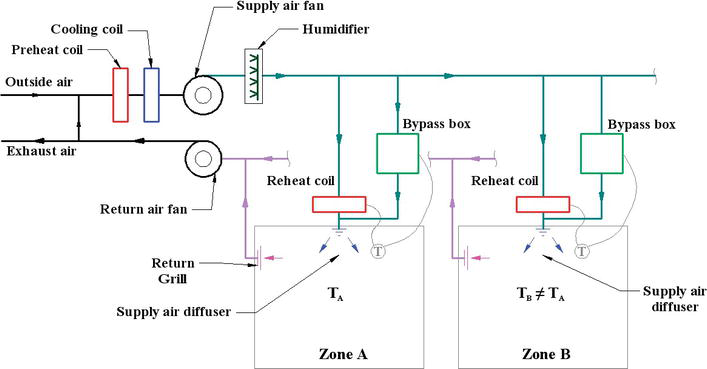

Terminal reheat

A terminal reheat all-air system is multiple zones, which considers an adaptation of a single-zone system, as shown in Figure 6. This can be performed by adding heating equipment, such as a hot water coil or an electric coil, to the downstream of the supply air from air handling units near each zone. Each zone is controlled by a thermostat to adjust the heat output of heating equipment to meet the thermal condition. The supply air from air handling units is cooled to the lowest cooling point, and the terminal reheat adds the required heating load. The advantage of terminal reheat is flexible and can be installed or removed to accommodate changes in zones, which provides better control of the thermal conditions in multiple zones. However, the design of terminal reheat is not an energy-efficient system because a significant amount of extremely cooling air is not regularly needed in zones, which can be considered waste energy. Therefore, energy codes and standards regulate the use of reheat systems.

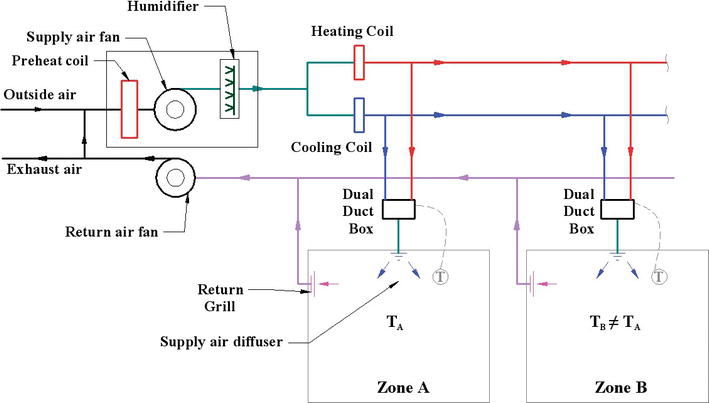

Dual duct

The dual duct all-air system is a terminal-controlled modification of the multi-zone concept. A central air handling unit provides two conditioned air streams such as a cold deck and a hot deck, as shown in Figure 7. These air streams are distributed throughout the area served by the air handling unit in separate and parallel ducts. Each zone has a terminal mixing box controlled by the zone thermostat to adjust the supply air temperature by mixing the supply cold and hot air. This type of system will minimize the disadvantages of previous systems and become more flexible by using terminal control.

All-water systems

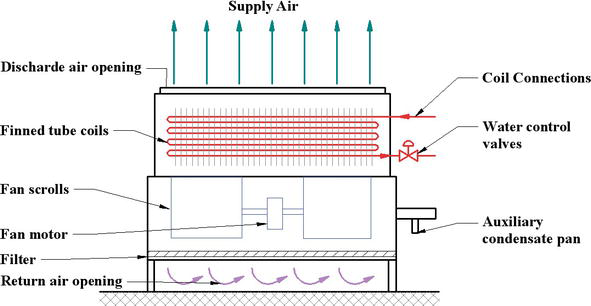

In an all-water system, heated and cooled water is distributed from a central system to conditioned spaces [4, 5]. This type of system is relatively small compared to other types because of the use of pipes as distribution containers and the water has higher heat capacity and density than air, which requires a lower volume to transfer heat. All-water heating-only systems include several delivery devices such as floor radiators, baseboard radiators, unit heaters, and convectors. However, all-water cooling-only systems are unusual such as valance units mounted on the ceiling. The primary type that is used in buildings to condition the entire space is a fan-coil unit. 6.2.1. Fan-coil units

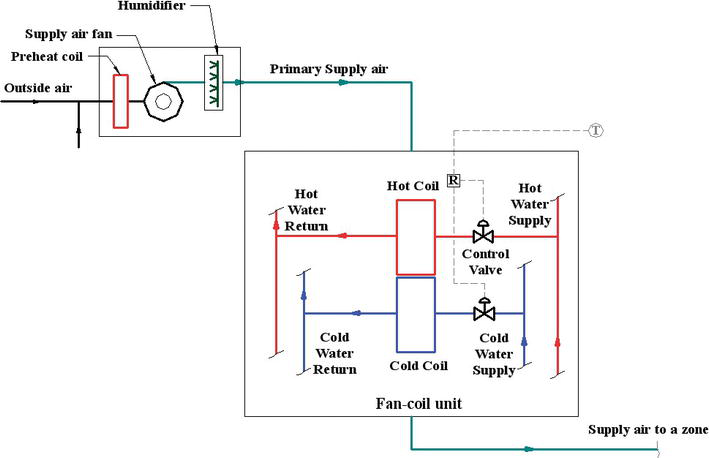

Fan-coil unit is a considerably small unit used for heating and cooling coils, circulation fan, and proper control system, as shown in Figure 9. The unit can be vertically or horizontally installed. The fan-coil unit can be placed in the room or exposed to occupants, so it is essential to have appropriate finishes and styling. For central systems, the fan-coil units are connected to boilers to produce heating and to water chillers to produce cooling to the conditioned space. The desired temperature of a zone is detected by a thermostat which controls the water flow to the fan-coil units. In addition, occupants can adjust fan coil units by adjusting supply air louvers to achieve the desired temperature. The main disadvantage of fan-coils is ventilation air and only can be solved if the fan-coil units are connected to outdoor air. Another disadvantage is the noise level, especially in critical places.

Air-water systems

Air-water systems are introduced as a hybrid system to combine both advantages of all-air and all-water systems [5]. The volume of the combined is reduced, and the outdoor ventilation is produced to properly condition the desired zone. The water medium is responsible for carrying the thermal load in a building by 80–90% through heating and cooling water, while the air medium conditions the remainder. There are two main types: fan-coil units and induction units.

Fan-coil units

Fan-coil units for air-water systems are similar to that of all-water systems except that the supply air and the conditioned water are provided to the desired zone from a central air handling unit and central water systems (e.g., boilers or chillers). The ventilation air can be separately delivered into space or connected to the fan-coil units. The major types of fan-coil systems, are 2 pipes or 4-pipes systems, as shown in Figure 10.

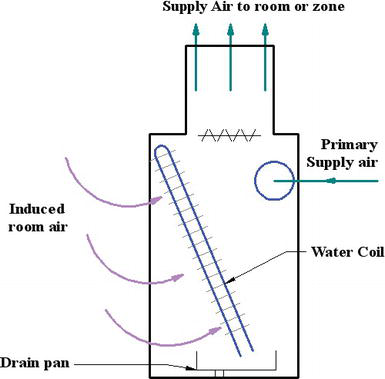

Induction units

Induction units are externally similar to fan-coil units but internally different. An induction unit induces the airflow in a room through a cabinet by using high-velocity airflow from a central air handling unit, which replaces the forced convection of the fan in the fan-coil by the induction or buoyancy effect of the induction unit, as shown in Figure 11. This can be performed by mixing the primary air from the central unit and the secondary air from the room to produce suitable and conditioned air in the room/zone.

Water-source heat pumps

Water-source heat pumps are used to provide considerable energy savings for large buildings under extreme cold weather [6]. A building of various zones can be conditioned by several individual heat pumps since each heat pump can be controlled according to the zone control. A centralized water circulation loop can be used as a heat source and heat sink for heat pumps. Therefore, heat pumps can act as the primary source of heating and cooling. The main disadvantage is the lack of air ventilation similar to the all-water systems as in fan-coil units. For a heating process, the boiler or solar collectors will be used to supply heat to the water circulation, while a cooling tower is used to reject heat collected from the heat pumps to the atmosphere. This system does not use chillers or any refrigeration systems. If a building requires a heating process for zones and a cooling process for other zones at the same time, the heat pump will redistribute heat from one part to another with no need for a boiler or cooling tower operation,

Heating and cooling panels

Heating and cooling panels are placed on floors or walls or ceilings that can be a source of heating and cooling [7]. They also can be called radiant panels. This type of system can be constructed as tubes or pipes impeded inside the surface where the cooling or heating media is circulated into the tubes to cool or heat the surface. The tubes are contacted to the adjacent large surface area to achieve the desired surface temperature for the cooling and heating process. The heat transfer process is mainly by the radiation mode between the occupants and the radiant panels, and the natural convection mode between the air and panels. Temperature restriction is recommended for radiant floor panels, a range of 66–84°F, to achieve thermal comfort for occupants (ASHRAE Standard 55). Radiant ceiling or wall panels can be used for the cooling and heating process. The surface temperature should be higher than the air dew point temperature to avoid condensation on the surface during the cooling process. Also, the maximum surface temperature is 140°F for ceiling levels at 10 ft. and 180°F for ceiling levels at 18 ft. This temperature is recommended to avoid too much heating above occupants’ heads.

The installation of such systems is often expensive compared to other types as mentioned above, but they can be useful and has a lower running cost mainly because of the surface temperature restriction. A control signal is connected to the thermostat of each zone to manipulate the medium temperature to condition the space. The used medium can be refrigerant or water mixed with inhibited glycol (anti-freeze) instead of plain water to prevent icing inside the tubes for the cooling process. The main advantage is no space required, only a few inches for the panels to be installed, and no more collected dirt in the standard ceiling or the ductwork. Many designs are available to produce attractive panels.

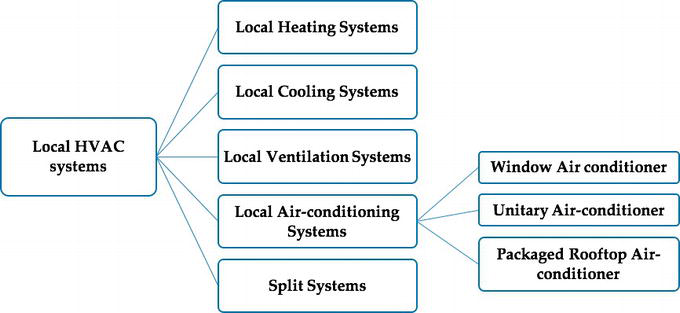

Local HVAC systems

Some buildings can have multiple zones or have a large, single zone, which needs central HVAC systems to serve and provide the thermal needs [4, 5]. However, other buildings may have a single zone that needs equipment located inside the zone itself, such as small houses and residential apartments. This type of system is considered a local HVAC system since each piece of equipment serves its zone without crossing boundaries to other adjacent zones (e.g., using an air conditioner to cool down a bedroom, or using an electrical heater for the living room). Therefore, a single zone requires only a one-point control point connected to a thermostat to activate the local HVAC system. Some buildings have multiple local HVAC systems as proper equipment serving specific single zones and controlled by the one-point control of the desired zone. However, these local systems are not connected and integrated to central systems, but are still part of a large full-building HVAC system. There are many types of local HVAC systems as shown in Figure 12.

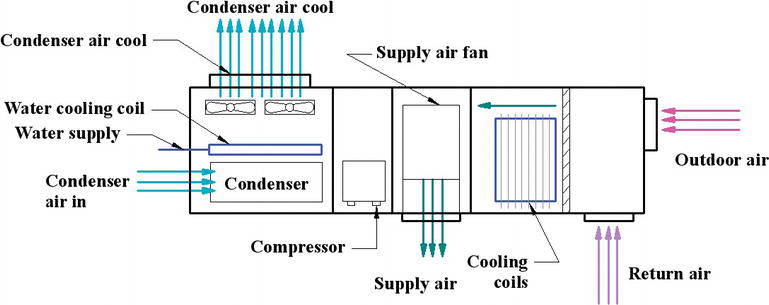

A packaged rooftop air-conditioner

It consists of a vapor compression refrigeration cycle; a heat source such as a heat pump and electric resistance; an air handler such as dampers, filters, and fans; and control devices, as shown in Figure 14. This system may be connected to ductwork and serve a large-size single zone that cannot be served by unitary or window air conditioners.

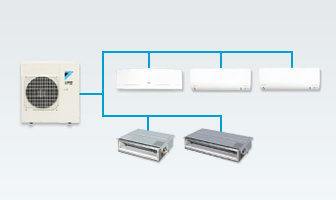

Split systems

The split systems contain two central devices [5, 6]: the condenser, located outdoor, and the evaporator, located indoors. The two devices are connected by a conduit for refrigerant lines and wiring. This system solves some issues of small-scale single-zone systems since the location and installation of window, unitary or rooftop air conditioners may affect the esthetic value and architectural design of the building. The split systems can contain one condenser unit and are connected to multiple evaporator units to serve as multiple zones as possible under the same conditions or different environmental conditions.

Conclusions: HVAC systems have several requirements including primary equipment such as heating equipment, cooling equipment, and delivery equipment; space requirements such as HVAC facilities, equipment room, and vertical shaft; air distribution; and piping. The type of HVAC systems can be divided into central HVAC systems and local HVAC systems. This classification depends on zone types and the location of HVAC equipment. The central HVAC systems can serve multiple and single zones and locate away from the building, which needs distribution devices. They also can be sub-classified into all-air HVAC systems, air-water systems, all-water systems, water-source heat pumps, and heating and cooling panel systems. The local HVAC systems are mostly placed inside or adjacent to the living spaces and serve one single zone. They consist of local heating systems, local air-conditioning systems, local ventilation systems, and split systems.

References:

1. ASHRAE Handbook. HVAC Systems and Equipment. Atlanta, GA: American Society of Heating, Refrigerating, and Air Conditioning Engineers; 1996. pp. 1-10

2. American Society of Heating, Refrigerating & Air-Conditioning Engineers. Heating, Ventilating, and Air-Conditioning: Systems and Equipment: 2000 ASHRAE Handbook: Inch-Pound. Amer Society of Heating; 2000

3. Sugarman SC. HVAC Fundamentals. 2nd ed. CRC Press, The Fairmont Press, Inc.; 2005

4. American Society of Heating, Refrigerating & Air-Conditioning Engineers. ASHRAE Handbook. Fundamentals: SI ed. Amer Society of Heating, Atlanta, GA; 2009

5. Haines RW, Myers ME. HVAC Systems Design Handbook. McGraw-Hill Education; 2010

6. ASHRAE Handbook. Fundamentals. Atlanta: American Society of Heating, Refrigerating and Air Conditioning Engineers; 2001. p. 111

7. Mumma SA. Ceiling panel cooling systems. ASHRAE Journal. 2001;43(11):28

8. Brumbaugh JE. Audel HVAC Fundamentals: Volume 1: Heating Systems, Furnaces, and Boilers. Vol. 17. Canada: John Wiley & Sons, Wiley Publishing, Inc.; 2004