Die casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminum, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. So basically it's injection molding with molten metal, neat.

The casting equipment and the metal dies to represent large capital costs and this tends to limit the process to high-volume production. The manufacture of parts using die casting is relatively simple, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small- to medium-sized castings, which is why die casting produces more castings than any other casting process. Die castings are characterized by a very good surface finish (by casting standards) and dimensional consistency.

History:

Die casting equipment was invented in 1838 to produce movable types for the printing industry. The first die casting-related patent was granted in 1849 for a small hand-operated machine for the purpose of mechanized printing type production. In 1885 Otto Mergenthaler invented the Linotype machine, which cast an entire line of type as a single unit, using a die casting process. It nearly completely replaced setting type by hand in the publishing industry. The Soss die-casting machine, manufactured in Brooklyn, NY, was the first machine to be sold in the open market in North America. Other applications grew rapidly, with die casting facilitating the growth of consumer goods, and appliances, by greatly reducing the production cost of intricate parts in high volumes. In 1966, General Motors released the Acura process.

Die Casting Advantages:

Die casting can have significant advantages over other manufacturing processes, which often lead to major cost savings, not only in the part price itself but also in the overall cost of production. When you cast a part, you can create complex net shapes, including external threads and complex internal features with minimal draft angles—minimizing secondary operations. You can also combine multiple parts into a single part, eliminating assembly operations and lowering labor costs, with the added benefits of simplified stock control and greater component consistency.

Other benefits include:

- Variable wall thicknesses

- Tighter tolerances

- Fewer steps from raw material to finished part

- Fast production cycle times

- Reduction in material scrap

- Long tool life, especially for zinc and magnesium

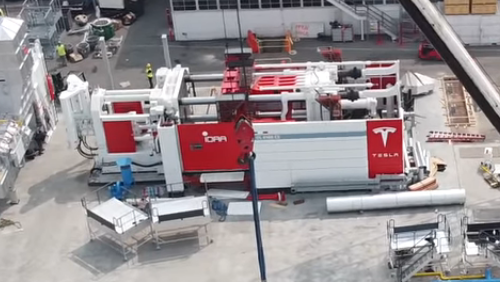

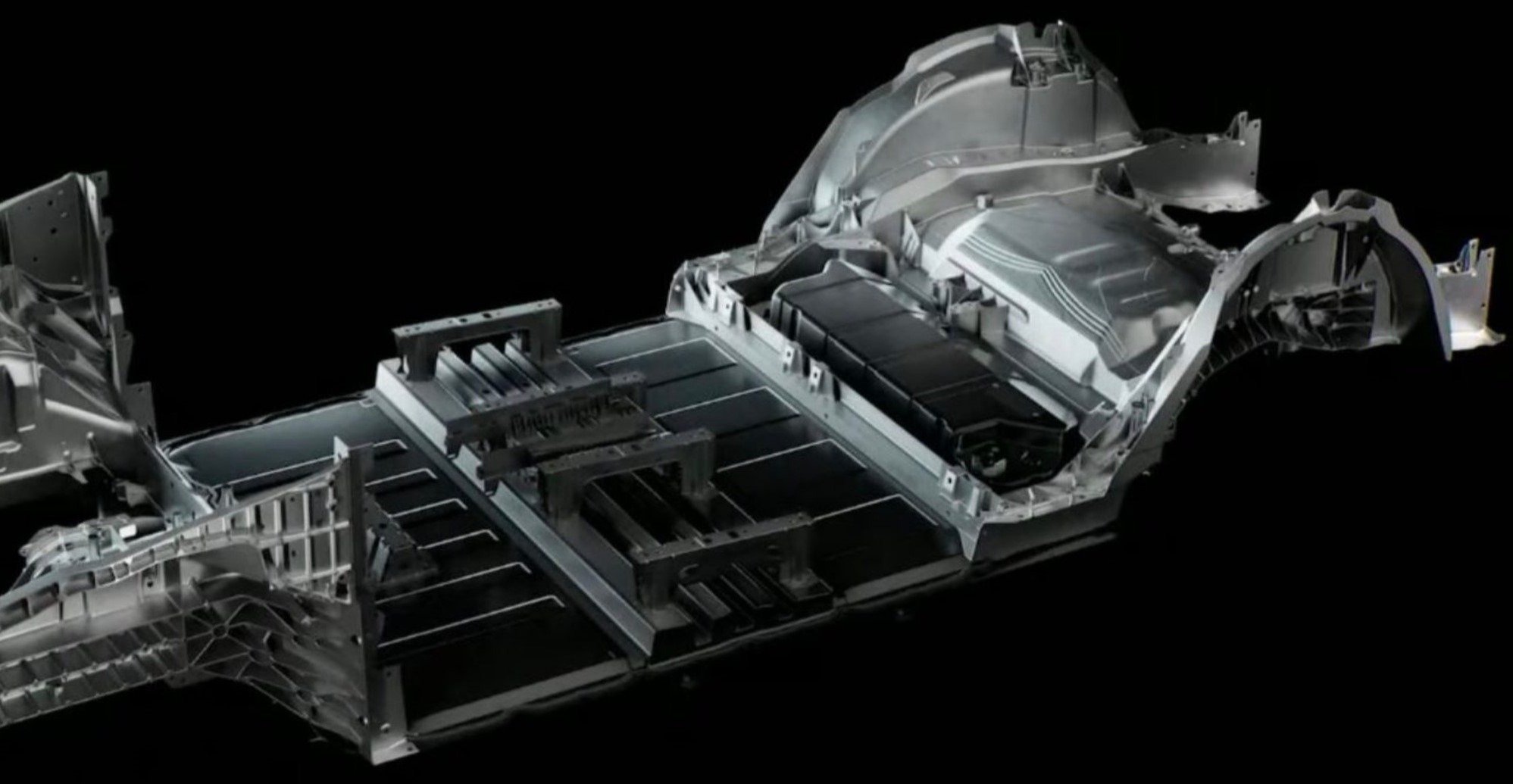

For example, Tesla plans to use 2 or 3 gigantic casting to make their cars, which is a new thing for the automotive industry this was never done before. They even manage to design a full mold to cast a whole car chassis. They call it the Giga press, it was made and designed in Italy by the Idra group.

They plan to use a 3-part casting which is a big assembly reduction compared to the "old" technique which is stamping. According to the internet with these manufacturing, they can out manufacture VW by a lot.

Die Casting Process:

There isn’t one single process that can suit every project. Each project is different which is why Dynacast offers multiple solutions for all die casting needs. This ensures the right process is always used for the right application.

The 3 different casting processes:

- Hot-Chamber

Used for zinc, some magnesium alloys, and other low-melting, hot-chamber die casting is a great option for alloys that do not readily attack and erode metal pots, cylinders, and plungers.

- Cold-Chamber

Better suited for metals with high melting points such as aluminum, during cold-chamber die casting, metal is liquefied and then ladled into a cold chamber where a hydraulically operated plunger pushes the metal into the die.

- Injected Metal Assembly

Injected Metal Assembly. IMA outperforms most adhesives used for small component joining and assembly production and reduces manufacturing costs.

Tooling:

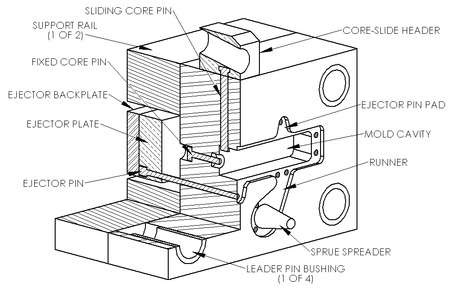

The die casting die or mold is a closed vessel into which molten metal is injected under high pressure and temperature, then rapidly cooled until the solidified part is sufficiently rigid to permit ejection from the mold.

Dies, or die casting tooling, are made of alloy tool steels in at least two sections, the fixed half (cover half) and the moving half (ejector die half), to permit removal of the castings. The dies also may have moveable slides, cores or other sections to produce holes, threads, and other desired shapes in the casting.

A hole in the fixed die half allows for the molten metal to enter the die and fill the cavity. The ejector half usually contains the runners (passageways) and gates (inlets) that route molten metal to the cavity. Dies also include locking pins to secure the two halves, ejector pins to help remove the cast part, and openings for coolant to help cool the mold and solidify the molten metal.

An essential accessory required to run any die cast mold is called a Shot Sleeve. The Shot Sleeve is a hollow tube that is inserted into the hole in the fixed half of the mold when it is set in the die cast machine. The Sleeve protrudes out from the die horizontally and there is a small opening in the top of the Sleeve where the molten metal is poured in preparation for the plunger to inject the metal into the mold. The Shot Sleeve needs replacement at certain intervals and is very important to the process. Quite often when molds are moved from a die caster, the Shot Sleeve is not sent with the mold which creates issues for the purchaser due to the lead time to fabricate a new Sleeve.

The two die halves run in a die casting machine that is operated at the required temperatures and pressures to produce a quality part to net-shape or near-net-shape customer specifications. When the die casting machine closes, the two die halves are locked and held together by the machine’s pressure. The surface where the ejector and the fixed halves of the die meet and lock are referred to as the “die parting line”. The total projected surface area of the part being cast, measured at the die parting line, governs the clamping force of the machine.

For longevity of operation in this environment, the die casting die must be built from high-quality tool steel of exacting specifications, heat-treated to the required hardness and structure, with dimensions of the die and cavity machined to exacting specifications.

The product design requirements directly affect the required tooling's size, type, features, and cost. The items involved in the tooling decision include the number of cavities, number of core or slide requirements, weight of the die, machining, finish requirements, polishing, and plating to name just a few.